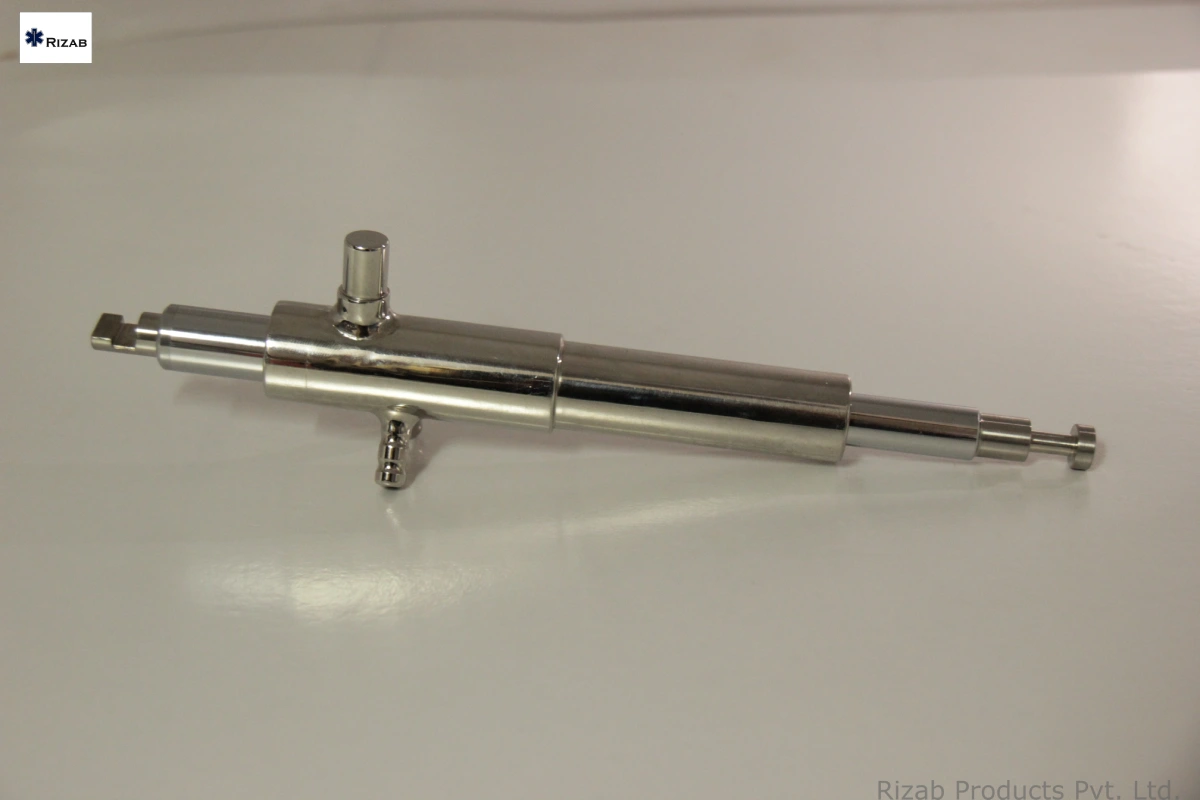

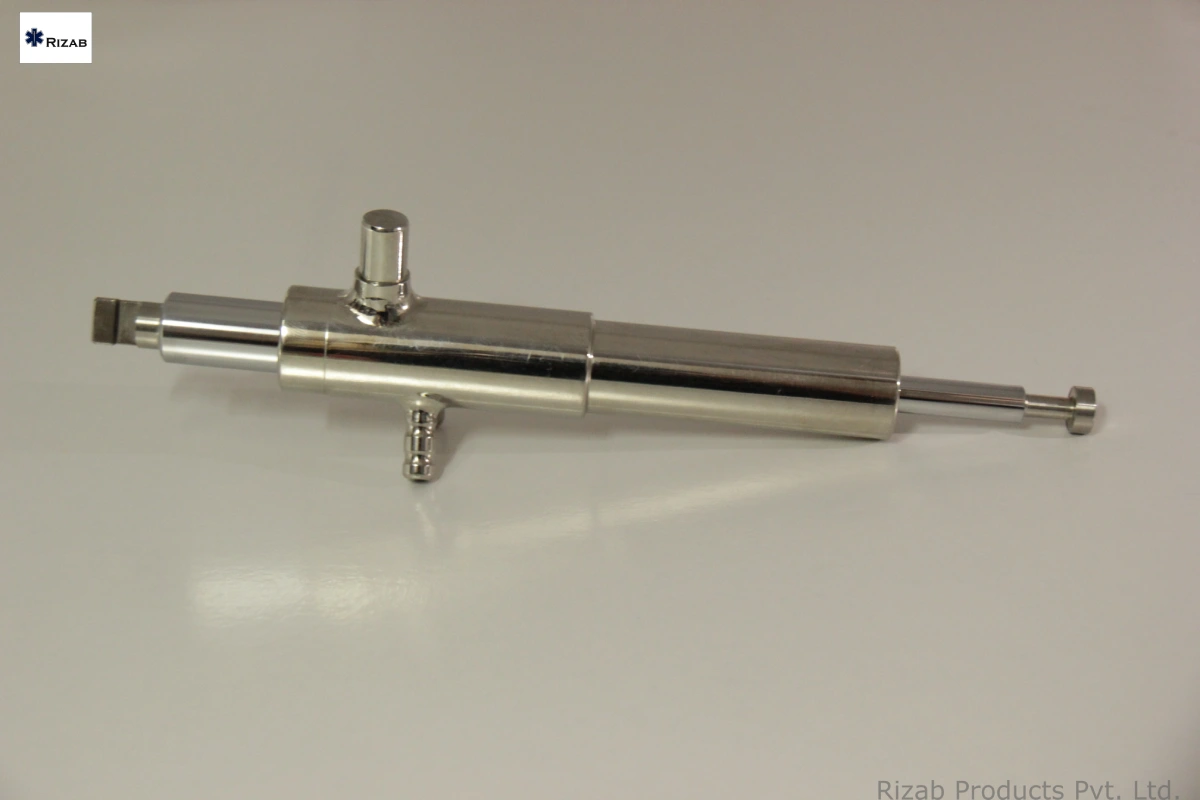

Syringe Dosing Pumps

- Home

- /

- Syringe Dosing Pumps

PRODUCT DESCRIPTION

Syringe dosing pumps are highly versatile, as they can be used for a wide range of liquids, from highly viscous fluids to thin, watery solutions. This makes them suitable for the pharmaceutical industry.

The syringe is filled with the dispensable fluid and attached to the pump mechanism. The pump then uses a piston to move the liquid out of the syringe and into the desired location. The precise control of the pump allows for accurate dosing of even tiny volumes.

One advantage of syringe dosing pumps is their ability to deliver precise and repeatable volumes, essential in many applications where accuracy is critical. They are also easy to use and maintain and can be programmed for automated operation.

A syringe dosing dump is a positive displacement pump that uses a syringe to move liquid through at a controlled rate. They use a pump mechanism to move the fluid from a storage container or reservoir and dispense it at a controlled rate and volume.

The pump mechanism can be powered by electricity, air pressure, or other means, depending on the specific type of dosing pump. It typically consists of a diaphragm or piston, which moves back and forth to create suction and pressure to move the fluid through the pump.

The dosing pump also has valves or other components to regulate the flow rate and volume and prevent leakage. The pump may be controlled by a timer or other electronic device, allowing for precise dosing according to a programmed schedule.

What are the parts of the syringe dosing pump? Syringe barrelThis is the main body of the syringe pump, which holds the liquid to be dispensed.

Pump mechanismThe pump mechanism moves back and forth to dispense the fluid, which can be motorized or manually controlled.

Control unitThe control unit allows the user to program the dosing pump to dispense a specific volume of fluid or gas at a particular rate and frequency.

TubingThe tubing connects the syringe to the pump mechanism and transfers the fluid between the two.

ValvesThe valves control the fluid flow and may be used to prevent backflow or leakage.

Mounting bracketsThe mounting brackets secure the dosing pump to a surface or stand and may be adjustable for different configurations.

Product Specification

Material of Construction :SS316LID and OD Contact Surface : Hard chrome Plated, Ground, Honed & Lapped to 0.07 Ra

Clearance between piston & cylinder: 0.002mm (Maximum)

Filling Accuracy : +/- = 1%

Filling Capacity : 0.5ml to 100ml

Diameter of Piston and cylinder: 6mm to 70ml

Length of Piston and Cylinder: 6mm to 70mm